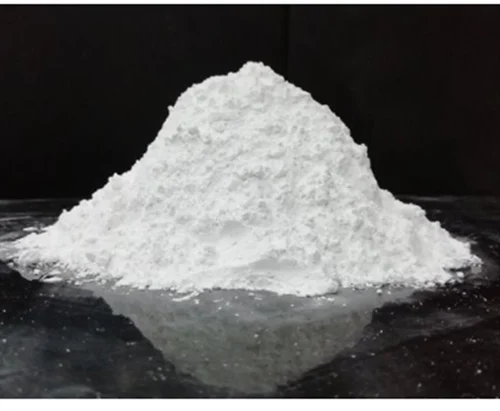

Ground Calcium Carbonate Manufacturer in India: Leading GCC Supplier and Solutions

India has established itself as a global leader in Ground Calcium Carbonate (GCC) manufacturing, with companies like Shikhar Microns setting industry standards for quality, innovation, and customer service. This comprehensive guide explores what makes a reliable GCC manufacturer and how to choose the right partner for your industrial applications.

Why Choose Indian GCC Manufacturers?

- Cost Competitive: Competitive pricing with global standards

- Quality Assurance: ISO certified manufacturing processes

- Technical Expertise: Decades of experience in mineral processing

- Custom Solutions: OEM and custom formulations

- Reliable Supply: Consistent quality and delivery

Key Factors in Choosing a GCC Manufacturer

1. Quality Standards and Certifications

A reliable Ground Calcium Carbonate manufacturer should maintain:

- ISO Certifications: Quality management systems

- Consistent Purity: ≥98% CaCO3 content

- Controlled PSD: Precise particle size distribution

- Quality Testing: In-house laboratory facilities

- Batch Traceability: Complete quality documentation

2. Manufacturing Capabilities

Look for manufacturers with:

- Advanced Equipment: Modern grinding and classification systems

- Production Capacity: Ability to meet large volume requirements

- Flexible Operations: Custom mesh sizes and formulations

- Quality Control: Rigorous testing at every stage

- Innovation: Continuous improvement in processes

3. Technical Support and Service

Choose manufacturers offering:

- Application Expertise: Industry-specific knowledge

- Formulation Support: Technical guidance for optimal usage

- Problem Solving: Troubleshooting and optimization

- Training Programs: Educational sessions for your team

- R&D Collaboration: Joint development projects

Shikhar Microns: Leading GCC Manufacturer

Shikhar Microns has established itself as a premier Ground Calcium Carbonate manufacturer in India, serving diverse industries with high-quality products and exceptional service.

Manufacturing Excellence

State-of-the-Art Facility

Modern manufacturing plant in Rajasthan

Quality Laboratory

In-house testing and quality control

Expert Team

Experienced technical professionals

Product Range and Specifications

| Parameter | Specification | Test Method |

|---|---|---|

| CaCO3 Content | ≥98% | Chemical Analysis |

| Mesh Size Range | 100-1500 | Sieve Analysis |

| Brightness | ≥95% | ISO 2470 |

| Oil Absorption | ≤25 g/100g | ISO 787-5 |

| Moisture Content | ≤0.2% | ISO 787-2 |

| pH Value | 8.5-9.5 | ISO 787-9 |

Industry Applications

Paints and Coatings

Ground Calcium Carbonate is extensively used in paint formulations for:

- Interior Paints: 400-500 mesh for smooth finish

- Exterior Paints: 270-400 mesh for durability

- Automotive Coatings: 635-800 mesh for premium finish

- Industrial Coatings: 200-325 mesh for cost optimization

Plastics and Polymers

In plastic applications, GCC provides:

- Injection Molding: 400-500 mesh for surface quality

- Extrusion: 270-400 mesh for flow properties

- Film & Sheet: 635-800 mesh for smooth surfaces

- Reinforced Plastics: 200-325 mesh for strength

Paper Industry

For paper applications:

- Filling: 200-400 mesh for bulk properties

- Coating: 400-800 mesh for smooth surfaces

- Printing Paper: 800-1500 mesh for fine finish

- Packaging Paper: 200-400 mesh for strength

Manufacturing Process

Our specialized manufacturing process ensures optimal properties for various applications:

- Raw Material Selection: High-grade limestone with consistent composition

- Precision Grinding: Controlled grinding to achieve specific mesh sizes

- Classification: Accurate particle size separation

- Quality Testing: Comprehensive testing for application compatibility

- Packaging: Contamination-free packaging for industrial use

OEM and Custom Solutions

Leading GCC manufacturers offer comprehensive OEM solutions:

Custom Formulations

- Specific Mesh Sizes: Any particle size distribution

- Surface Treatments: Stearic acid coating for enhanced properties

- Chemical Modifications: Adjusted pH and reactivity

- Color Matching: Custom whiteness and brightness

Packaging Solutions

- Standard Bags: 25kg, 50kg, 1-ton bags

- Bulk Containers: Container loading for large volumes

- Custom Packaging: Branded packaging solutions

- Just-in-Time Delivery: Scheduled deliveries

Quality Assurance and Testing

Reputable GCC manufacturers maintain rigorous quality control:

Testing Procedures

- Chemical Analysis: CaCO3 content verification

- Particle Size Analysis: Mesh size distribution testing

- Physical Properties: Brightness, oil absorption, moisture

- Performance Testing: Application-specific testing

- Contamination Testing: Purity and cleanliness verification

Quality Documentation

- Certificates of Analysis: Detailed test results

- Material Safety Data Sheets: Safety information

- Quality Certificates: ISO and industry certifications

- Batch Traceability: Complete production records

Supply Chain and Logistics

Reliable manufacturers ensure efficient supply chain management:

Production Planning

- Demand Forecasting: Accurate production planning

- Inventory Management: Optimal stock levels

- Production Scheduling: Efficient resource utilization

- Quality Control: Continuous monitoring

Distribution Network

- Pan-India Coverage: Nationwide distribution

- Export Capabilities: Global shipping

- Warehouse Network: Strategic storage locations

- Transportation: Reliable logistics partners

Performance Comparison

Ground Calcium Carbonate offers several advantages over other fillers:

vs. Dolomite Powder

- Higher brightness (≥95% vs ≥90%)

- Lower oil absorption

- Better whiteness

- More consistent quality

vs. Clay Fillers

- Higher brightness

- Lower oil absorption

- Better flow properties

- More stable pH

Manufacturer Advantage

Choosing a direct manufacturer like Shikhar Microns ensures competitive pricing, consistent quality, reliable supply, and direct technical support. This eliminates middlemen and provides better value for your investment.

Future Trends in GCC Manufacturing

The Ground Calcium Carbonate manufacturing industry is evolving with new trends:

- Sustainability: Eco-friendly manufacturing processes

- Digitalization: Smart manufacturing and IoT integration

- Innovation: Advanced surface treatments and modifications

- Customization: Tailored solutions for specific applications

- Quality Enhancement: Continuous improvement in product quality

Partner with India's Leading Ground Calcium Carbonate Manufacturer

Contact Shikhar Microns for expert consultation and customized solutions