Ground Calcium Carbonate (GCC) for Paper Industry: Filler and Coating Applications

Ground Calcium Carbonate (GCC) has revolutionized the paper industry by providing cost-effective, high-performance filler and coating solutions. This comprehensive guide explores how GCC enhances paper quality, reduces manufacturing costs, and improves printability while maintaining environmental sustainability.

Paper Industry Benefits

- Improved brightness and opacity

- Enhanced print quality

- Reduced production costs

- Better paper strength

Understanding GCC in Paper Manufacturing

Ground Calcium Carbonate (GCC) is a naturally occurring mineral that has become the preferred filler and coating material in modern paper production. Its unique properties make it ideal for enhancing paper characteristics while reducing the reliance on expensive wood pulp.

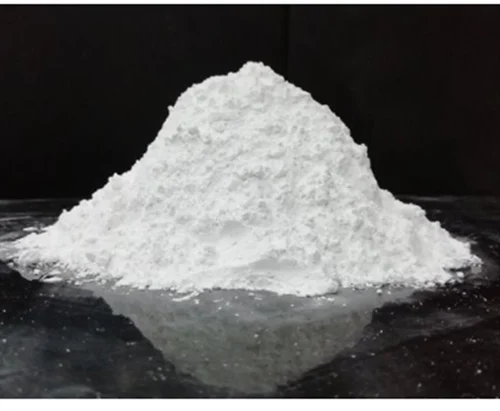

GCC is produced by grinding natural limestone or marble to specific particle sizes, creating a white, bright powder that significantly improves paper quality and manufacturing efficiency. The mineral's high brightness, low cost, and excellent compatibility with paper-making processes make it indispensable in the industry.

Key Applications of GCC in Paper Industry

1. Paper Filler Applications

GCC serves as an excellent filler material, replacing expensive wood pulp while improving paper properties. It enhances brightness, opacity, and smoothness while reducing production costs.

2. Paper Coating Applications

As a coating pigment, GCC provides superior printability, surface smoothness, and ink receptivity. It creates a uniform surface that enhances print quality and reduces ink consumption.

3. Specialty Paper Production

GCC is used in producing specialty papers including photographic papers, label papers, and high-quality printing papers where superior surface properties are essential.

4. Recycled Paper Enhancement

GCC helps improve the quality of recycled paper by compensating for the loss of brightness and strength that occurs during the recycling process.

Benefits of Using GCC in Paper Manufacturing

Cost Reduction

GCC is significantly less expensive than wood pulp, allowing paper manufacturers to reduce raw material costs while maintaining or improving paper quality.

Improved Paper Properties

GCC enhances several key paper properties including brightness, opacity, smoothness, and printability, resulting in higher-quality end products.

Environmental Benefits

Using GCC reduces the demand for wood pulp, contributing to forest conservation and sustainable paper production practices.

Process Efficiency

GCC improves paper machine runnability, reduces downtime, and enhances overall production efficiency in paper manufacturing facilities.

GCC Specifications for Paper Applications

Particle Size

Fine particles (0.5-2 microns) for coating applications, coarser particles (2-10 microns) for filler applications.

Brightness

High brightness levels (90%+) to enhance paper whiteness and print contrast.

Paper Types and GCC Applications

Newsprint and Magazine Papers

GCC is extensively used in newsprint and magazine papers to improve brightness and reduce costs while maintaining print quality.

Office and Copy Papers

High-quality office papers benefit from GCC's ability to enhance brightness, smoothness, and printability for professional documents.

Packaging Papers

GCC improves the appearance and printability of packaging materials while providing cost-effective solutions for various packaging applications.

Label and Specialty Papers

Specialty papers require high-quality GCC to achieve superior surface properties and print quality for demanding applications.

Manufacturing Process Integration

GCC integration into paper manufacturing involves several key steps:

- Slurry Preparation: GCC is mixed with water to create a stable slurry for addition to the paper stock

- Retention Optimization: Proper retention aids ensure maximum GCC retention in the paper sheet

- Drainage Control: GCC particle size affects drainage rates and must be optimized for each paper grade

- Quality Monitoring: Continuous monitoring ensures consistent GCC performance and paper quality

Quality Control and Testing

Effective GCC quality control involves testing for:

- Particle size distribution and surface area

- Brightness and whiteness measurements

- Chemical purity and impurity levels

- Rheological properties for coating applications

- Compatibility with paper-making chemicals

Best Practice

Regular testing and quality control ensure optimal GCC performance in paper manufacturing. Work with suppliers who provide consistent quality and technical support.

Future Trends in GCC Usage

The paper industry continues to evolve with increasing emphasis on:

- Sustainability: Greater use of GCC to reduce environmental impact

- Digital Printing: Specialized GCC grades for digital printing applications

- Recycled Content: Enhanced GCC formulations for recycled paper grades

- Performance Optimization: Advanced GCC products for specific paper applications

Conclusion

Ground Calcium Carbonate (GCC) has become an essential component in modern paper manufacturing, providing cost-effective solutions that enhance paper quality while supporting sustainable production practices. Its versatility in both filler and coating applications makes it indispensable for paper manufacturers worldwide.

At Shikhar Microns, we provide high-quality GCC specifically processed for paper industry applications, ensuring consistent performance and optimal results for our customers' paper manufacturing needs.