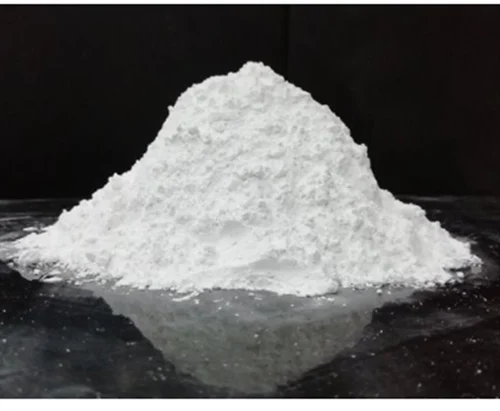

Ground Calcium Carbonate (GCC) for Plastic Industry: Filler and Reinforcement Applications

Ground Calcium Carbonate (GCC) has become an indispensable component in the plastic industry, providing cost-effective filler solutions that enhance material properties while reducing production costs. This comprehensive guide explores how GCC transforms plastic manufacturing through improved performance, sustainability, and economic benefits.

Plastic Industry Benefits

- Cost reduction

- Improved stiffness

- Enhanced dimensional stability

- Better processability

Understanding GCC in Plastic Manufacturing

Ground Calcium Carbonate (GCC) serves as a functional filler in plastic manufacturing, offering numerous advantages over traditional plastic materials. Its unique properties make it ideal for enhancing plastic performance while maintaining cost-effectiveness and environmental sustainability.

GCC is particularly valuable in plastic applications due to its high whiteness, low cost, and excellent compatibility with various polymer systems. The mineral filler improves mechanical properties, reduces material costs, and enhances processing characteristics in plastic manufacturing.

Key Applications of GCC in Plastic Industry

1. Polyvinyl Chloride (PVC) Applications

GCC is extensively used in PVC products including pipes, profiles, and films. It improves stiffness, dimensional stability, and weatherability while reducing material costs.

2. Polyethylene (PE) and Polypropylene (PP)

In PE and PP applications, GCC enhances stiffness, improves heat resistance, and reduces shrinkage. It's commonly used in packaging films, containers, and automotive parts.

3. Engineering Plastics

GCC finds applications in engineering plastics where improved mechanical properties and cost reduction are essential for competitive manufacturing.

4. Biodegradable Plastics

GCC is increasingly used in biodegradable plastic formulations to improve properties while maintaining environmental benefits.

Benefits of GCC in Plastic Manufacturing

Cost Reduction

GCC is significantly less expensive than polymer resins, allowing manufacturers to reduce raw material costs while maintaining or improving product performance.

Improved Mechanical Properties

GCC enhances stiffness, impact resistance, and dimensional stability in plastic products, making them more suitable for demanding applications.

Enhanced Processing

GCC improves melt flow properties, reduces cycle times, and enhances mold filling characteristics in plastic processing operations.

Environmental Benefits

Using GCC reduces the consumption of petroleum-based polymers, contributing to more sustainable plastic manufacturing practices.

GCC Specifications for Plastic Applications

Particle Size

Fine particles (1-3 microns) for thin films, coarser particles (3-10 microns) for thick sections and profiles.

Loading Levels

Typical loading levels range from 5-40% depending on application requirements and performance targets.

Plastic Product Categories and GCC Usage

Packaging Applications

GCC is widely used in plastic packaging including films, containers, and bottles to improve stiffness and reduce costs while maintaining clarity and barrier properties.

Automotive Components

Automotive plastic parts benefit from GCC's ability to improve dimensional stability, reduce weight, and lower material costs in various components.

Construction Materials

PVC pipes, profiles, and construction films use GCC to enhance durability, weather resistance, and cost-effectiveness in building applications.

Consumer Goods

Household items, toys, and consumer products utilize GCC to improve properties while maintaining competitive pricing in the consumer market.

Processing Considerations

Successful GCC integration in plastic manufacturing requires attention to several key factors:

- Dispersion: Proper dispersion of GCC particles ensures uniform properties throughout the plastic matrix

- Surface Treatment: Coated GCC grades improve compatibility and dispersion in polymer systems

- Processing Temperature: GCC is stable at typical plastic processing temperatures

- Mixing Equipment: High-shear mixing equipment ensures optimal GCC dispersion

Quality Control and Testing

Effective GCC quality control for plastic applications includes testing for:

- Particle size distribution and surface area

- Chemical purity and moisture content

- Brightness and color properties

- Dispersion characteristics in polymer systems

- Impact on mechanical properties

Technical Tip

Surface-treated GCC grades offer better dispersion and improved mechanical properties in plastic applications. Consider coated grades for demanding applications.

Future Trends and Innovations

The plastic industry continues to evolve with GCC applications, focusing on:

- Nano-sized GCC: Ultra-fine particles for enhanced properties in specialty applications

- Functional Coatings: Advanced surface treatments for improved polymer compatibility

- Sustainable Solutions: GCC in biodegradable and recyclable plastic formulations

- High-Loading Applications: Optimized formulations for maximum cost reduction

Conclusion

Ground Calcium Carbonate (GCC) has revolutionized plastic manufacturing by providing cost-effective filler solutions that enhance material properties while supporting sustainable production practices. Its versatility across various plastic applications makes it an essential component for competitive plastic manufacturing.

At Shikhar Microns, we provide high-quality GCC specifically processed for plastic industry applications, ensuring optimal performance and cost-effectiveness for our customers' manufacturing needs.