Mineral Fillers in Industrial Applications: Complete Guide

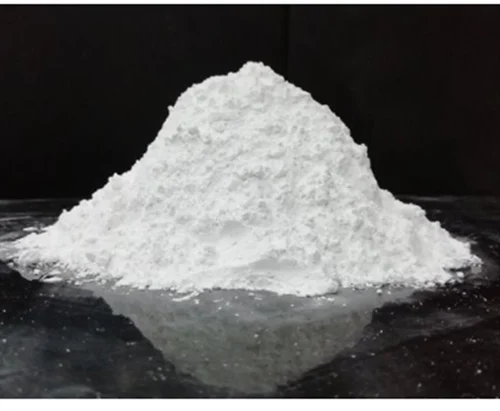

Mineral fillers play a crucial role in modern industrial applications, providing cost-effective solutions while enhancing product performance across multiple industries. From plastics and paints to paper and rubber, these versatile materials offer numerous benefits that make them indispensable in manufacturing processes.

What Are Mineral Fillers?

Mineral fillers are finely ground natural minerals that are added to various materials to improve their properties, reduce costs, and enhance performance. The most commonly used mineral fillers include:

- Calcite (Calcium Carbonate) - The most widely used mineral filler

- Dolomite (Calcium Magnesium Carbonate) - Known for its hardness and durability

- Limestone (Calcium Carbonate) - Cost-effective and versatile

- Kaolin (Clay) - Excellent for paper and ceramics

- Talc - Used for its lubricating properties

Key Properties of Mineral Fillers

Understanding the properties of mineral fillers is essential for selecting the right material for specific applications:

Physical Properties

- Particle Size: Ranges from 0.1 to 50 microns, affecting dispersion and performance

- Brightness: 85-98% depending on mineral type and processing

- Oil Absorption: 15-35 g/100g, affecting viscosity and flow properties

- Moisture Content: Typically less than 0.5% for optimal performance

Chemical Properties

- pH Value: 8.0-9.5 for calcium-based fillers

- Chemical Inertness: Non-reactive in most applications

- Thermal Stability: Stable up to 800°C

- Acid Resistance: Varies by mineral type

Industrial Applications of Mineral Fillers

1. Plastics Industry

Mineral fillers are extensively used in plastic manufacturing to improve mechanical properties and reduce costs:

- PVC Applications: Pipes, profiles, and films benefit from improved stiffness and dimensional stability

- Polyethylene: Films and sheets gain enhanced mechanical properties

- Polypropylene: Automotive parts and packaging materials

- Benefits: Reduced material costs, improved stiffness, better dimensional stability

2. Paints and Coatings

In the paint industry, mineral fillers serve as extender pigments:

- Interior Paints: Improve coverage and reduce costs

- Exterior Paints: Enhance durability and weather resistance

- Primers: Improve adhesion and surface preparation

- Benefits: Reduced titanium dioxide usage, improved coverage, better flow properties

3. Paper Industry

Mineral fillers are crucial in paper manufacturing:

- Filler Applications: Up to 30% loading in paper pulp

- Coating Pigments: High-quality paper coatings

- Benefits: Improved brightness, opacity, printability, and cost reduction

4. Rubber Industry

Mineral fillers enhance rubber properties:

- Tire Manufacturing: Improved tread wear and rolling resistance

- Rubber Sheets: Enhanced mechanical properties

- Benefits: Improved tensile strength, abrasion resistance, and cost reduction

5. Construction Materials

Construction applications benefit from mineral fillers:

- Concrete Additives: Improved workability and strength

- Tile Adhesives: Enhanced bonding properties

- Benefits: Reduced shrinkage, improved workability, cost savings

Selection Criteria for Mineral Fillers

Choosing the right mineral filler depends on several factors:

Application Requirements

- End-use Properties: Mechanical, optical, and chemical requirements

- Processing Conditions: Temperature, pressure, and mixing requirements

- Cost Considerations: Balance between performance and economics

Technical Specifications

- Particle Size Distribution: Affects dispersion and final properties

- Brightness and Whiteness: Important for appearance applications

- Oil Absorption: Affects viscosity and processing

- Moisture Content: Critical for processing stability

Benefits of Using Mineral Fillers

Cost Benefits

- Reduced material costs (up to 40% savings)

- Lower energy consumption during processing

- Improved production efficiency

Performance Benefits

- Enhanced mechanical properties

- Improved dimensional stability

- Better surface finish and appearance

- Increased product durability

Environmental Benefits

- Reduced use of synthetic materials

- Lower carbon footprint

- Improved recyclability

Quality Control and Testing

Ensuring consistent quality is essential for mineral filler applications:

Key Test Parameters

- Particle Size Analysis: Laser diffraction and sieve analysis

- Brightness Measurement: ISO 2470 standard

- Oil Absorption: ASTM D281 standard

- Moisture Content: ASTM D280 standard

- Chemical Composition: XRF analysis

Quality Standards

- ISO 9001:2015 quality management

- Industry-specific standards (ASTM, DIN, JIS)

- Customer-specific requirements

Future Trends in Mineral Filler Applications

The mineral filler industry is evolving with new technologies and applications:

Emerging Applications

- Biodegradable Plastics: Enhanced with mineral fillers

- Smart Materials: Functional fillers for advanced applications

- 3D Printing: Specialized fillers for additive manufacturing

Technological Advances

- Surface Treatment: Improved dispersion and compatibility

- Nano-fillers: Enhanced properties at lower loadings

- Sustainable Processing: Environmentally friendly production methods

Conclusion

Mineral fillers are essential components in modern industrial applications, offering cost-effective solutions while enhancing product performance. Understanding their properties, applications, and selection criteria is crucial for achieving optimal results in various industries.

At Shikhar Microns, we provide high-quality mineral fillers tailored to your specific requirements. Our expertise in mineral processing and commitment to quality ensures that you receive the best possible solutions for your industrial applications.