Shikhar Microns: Your Trusted Partner for Premium Ground Calcium Carbonate (GCC) in India

Shikhar Microns stands among the top Ground Calcium Carbonate (GCC) manufacturers in India. Our products meet international quality benchmarks and earn global trust. Our team collaborates with you to deliver the perfect solution for your requirements. Backed by over 27 years of expertise and a commitment to innovation, we ensure that our ground calcium carbonate delivers consistent results for every application.

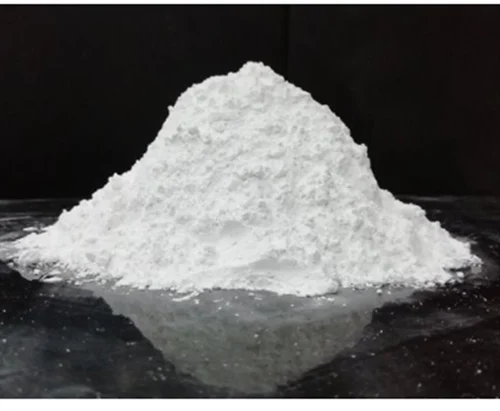

What is Ground Calcium Carbonate (GCC)?

Ground Calcium Carbonate (GCC) is produced by grinding naturally occurring calcium carbonate rocks to achieve specific particle size distributions. It is widely recognized for its exceptional brightness, cost-effectiveness, and superior dispersion properties. Due to its unique characteristics, industries worldwide use this fine white powder as a functional filler and performance enhancer in their manufacturing operations.

Chemical Composition and Physical Characteristics

Shikhar Microns ensures both the quality and purity standards of our ground calcium carbonate production. Our product offers:

Chemical Composition:

- Calcium Carbonate (CaCO₃): 97-99%

- Magnesium Carbonate (MgCO₃): 0.5-2%

- Silica (SiO₂): <1.0%

- Iron Oxide (Fe₂O₃): <0.1%

- Aluminum Oxide (Al₂O₃): <0.3%

Physical Features:

- Brightness: 92-96% (ISO 2470)

- Whiteness: 92-96% (Hunter L scale)

- Oil Absorption: 18-28 g/100g

- Moisture Content: ≤0.3%

- pH Value: 8.0-9.0

- Specific Gravity: 2.7-2.8

- Bulk Density: 0.8-1.2 g/cm³

Key Features of Our Ground Calcium Carbonate (GCC)

Our Ground Calcium Carbonate (GCC) meets all industry demands and requirements because of its specific technical aspects:

- Exceptional Brightness: 92-96% brightness provides excellent opacity and coverage

- Cost-Effective Solution: Provides excellent value for money compared to other fillers

- Low Oil Absorption: 18-28 g/100g reduces binder requirements and costs

- Excellent Dispersibility: Uniform particle distribution for consistent results

- Chemical Stability: Resistant to acids, alkalis, and temperature variations

- Free-Flowing Nature: Easy handling and processing in manufacturing

- Controlled Particle Size: Available in 100-1500 mesh for various applications

Uses of Ground Calcium Carbonate (GCC) in Various Industries

Our ground calcium carbonate serves as a versatile filler and functional additive across multiple industries:

Paper Manufacturing

In paper production, ground calcium carbonate serves as a filler and coating pigment, improving brightness, opacity, and printability while reducing production costs and environmental impact. It's the most widely used filler in the paper industry.

Plastic and Polymer Industry

As a functional filler in plastics, ground calcium carbonate improves mechanical properties, reduces material costs, and enhances dimensional stability. It's widely used in PVC pipes, profiles, films, and injection-molded products.

Paint and Coating Industry

In paints and coatings, ground calcium carbonate acts as an extender pigment that improves opacity, reduces costs, and enhances durability. It provides excellent coverage, weather resistance, and helps control viscosity for better application properties.

Rubber Industry

Rubber manufacturers use ground calcium carbonate to improve processing characteristics, enhance mechanical properties, and reduce costs in tire manufacturing, footwear, and industrial rubber products.

Adhesives and Sealants

In adhesives and sealants, ground calcium carbonate improves rheological properties, enhances bonding strength, and provides cost-effective filler solutions for various applications.

How We Make the Best Ground Calcium Carbonate (GCC) in India

At Shikhar Microns, our manufacturing process ensures the highest quality ground calcium carbonate that meets international standards:

1. Raw Material Selection

We source premium-grade calcium carbonate rocks from certified mines, ensuring high calcium carbonate content and minimal impurities. Our strict quality control begins at the source.

2. Crushing and Grinding

Our state-of-the-art crushing and grinding equipment processes the raw material through multiple stages, achieving precise particle size distribution and optimal surface characteristics.

3. Classification and Screening

Advanced air classification and screening systems ensure consistent particle size distribution, meeting specific mesh requirements for different applications.

4. Quality Control and Testing

Every batch undergoes rigorous testing for purity, brightness, particle size, moisture content, and other critical parameters to ensure consistent quality.

5. Packaging and Storage

Our ground calcium carbonate is carefully packaged in moisture-resistant materials and stored in controlled conditions to maintain quality until delivery.

Why Choose Shikhar Microns for Ground Calcium Carbonate (GCC)?

With over 27 years of experience in mineral processing, Shikhar Microns has established itself as a trusted ground calcium carbonate manufacturer in India. Here's why industry leaders choose us:

1. Unmatched Quality and Consistency

Our advanced manufacturing processes and strict quality control ensure that every batch of ground calcium carbonate meets the highest purity and performance standards.

2. Customized Solutions

We understand that different applications require specific properties. Our team works closely with clients to provide customized ground calcium carbonate solutions that meet exact requirements.

3. Competitive Pricing

Our efficient manufacturing processes and direct sourcing enable us to offer competitive prices without compromising on quality.

4. Reliable Supply Chain

With our own manufacturing facilities and strategic partnerships, we ensure consistent supply and timely delivery to meet your production schedules.

5. Technical Support

Our experienced technical team provides comprehensive support, from product selection to application guidance, ensuring optimal results for your specific needs.

6. Environmental Responsibility

We are committed to sustainable manufacturing practices, minimizing environmental impact while maintaining the highest quality standards.

Properties

- High brightness and purity

- Low oil absorption

- Excellent dispersion

- Stable chemical composition

- Fine particle size distribution

Technical Specifications

| CaCO3 Content | ≥ 99.0% |

| Whiteness | ≥ 96% |

| Mesh Sizes Available | 200, 300, 400, 500, 600, 800, 1000, 1250, 1500 |

| Moisture Content | ≤ 0.1% |

| Oil Absorption | ≤ 22 g/100g |

| pH Value | 8.0 - 9.0 |

Applications and Uses of Ground Calcium Carbonate (GCC)

Our ground calcium carbonate serves as a versatile functional filler across multiple industries, providing cost-effective solutions while enhancing product performance.

1. Paper Industry

GCC is extensively used in paper manufacturing as a filler and coating pigment. It improves paper brightness, opacity, and printability while reducing production costs.

- Filler in paper pulp (up to 30% loading)

- Coating pigment for high-quality papers

- Improves paper smoothness and print quality

- Reduces fiber usage and production costs

2. Plastics Industry

In plastic manufacturing, GCC acts as a functional filler that improves mechanical properties and reduces material costs.

- PVC pipes and profiles (up to 40% loading)

- Polyethylene films and sheets

- Improves stiffness and dimensional stability

- Reduces material costs significantly

3. Paints and Coatings

GCC serves as an extender pigment in paint formulations, improving coverage and reducing costs.

- Interior and exterior paints

- Primers and undercoats

- Improves paint coverage and durability

- Reduces titanium dioxide requirements

4. Construction Materials

GCC is used in various construction applications as a filler and performance enhancer.

- Concrete and mortar additives

- Tile adhesives and grouts

- Improves workability and strength

- Reduces shrinkage and cracking

5. Rubber Industry

In rubber manufacturing, GCC improves processing characteristics and end-product properties.

- Tire manufacturing

- Rubber sheets and hoses

- Improves tensile strength and abrasion resistance

- Reduces material costs

Frequently Asked Questions

PCC (Precipitated Calcium Carbonate): Chemically synthesized, uniform particle shapes, higher purity but more expensive

Related GCC Resources

Ground Calcium Carbonate Manufacturer

Complete guide on choosing the right GCC manufacturer in India for your industrial applications.

Read Article